[STARTUP]REPLA Overcomes Recycling Limits of Mixed Plastic Waste with Microbe-Based Selective Degradation Technology

Biological recycling system enables high-purity polypropylene recovery at room temperature

REPLA, a South Korea–based plastic recycling startup, announced the development of a microbe-based biological recycling system that addresses one of the most persistent challenges in plastic recycling: the low purity and poor performance of recycled materials derived from mixed plastic waste.

By leveraging microorganisms with selective degradation capabilities, REPLA’s technology selectively removes unwanted polymers—such as polyethylene (PE)—from mixed plastic waste streams, significantly increasing the purity of polypropylene (PP). The approach is gaining attention as a next-generation materials recycling solution capable of overcoming the structural limitations of conventional mechanical recycling.

Low-Energy, Low-Carbon Recycling at Room Temperature

Unlike chemical or thermal decomposition methods, REPLA’s biological process operates at room temperature (25–30°C) and does not require complex polymer repolymerization. This results in substantially lower energy consumption and reduced carbon emissions.

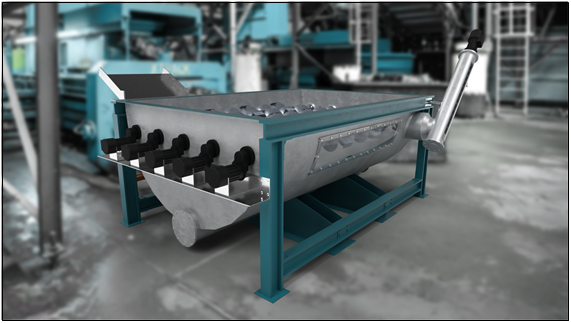

The system can be integrated into existing recycling plants, enabling operators to convert low-grade mixed plastic waste into high-purity, single-material feedstock without major infrastructure changes.

“Our technology enables an eco-friendly recycling process that runs at ambient temperatures while targeting only unwanted materials,” said a REPLA spokesperson. “This allows recycling facilities to improve material quality without increasing operational complexity or environmental burden.”

Verified Performance Improvements

According to test results from the Korea Polymer Research Institute, plastics processed using REPLA’s microbial system demonstrated significant improvements in physical properties:

- 67% increase in tensile strength

- 29% increase in flexural strength

In addition, harmful additives and byproducts were reduced, including:

- 10.5% reduction in volatile organic compounds (VOCs)

- 17.4% reduction in phenolic antioxidants

The microbial culture medium used in the process is reusable, and the microorganisms self-propagate, enhancing both operational efficiency and long-term sustainability.

Scaling Toward Commercial Deployment

REPLA has raised a total of KRW 13.35 billion (approximately USD 10 million) to date and is currently establishing a recycling plant near Hwaseong, Gyeonggi Province, to support equipment demonstration and scale-up.

The company plans to complete development of a 400-ton-per-year purity-enhancement facility by 2025, followed by expansion to a 10,000-ton annual capacity by 2026, targeting deployment across global recycling facilities.

Award-Winning Plastic Analysis Solutions

In addition to its microbial degradation technology, REPLA offers a suite of plastic analysis and identification tools designed to improve transparency and trust in the recycled plastics market.

plaSCAN is a lightweight (230g) handheld scanner that can instantly identify nine types of plastic with a single scan. The device has been widely adopted across industrial sites and received CES Innovation Awards in the categories of Product in Support of Human Security and Sustainability & Energy Transition.

PuriChecker is a precision analysis system that provides data-driven quality reports by analyzing plastic composition ratios, colors, and metal content. The system can analyze a 2kg sample within three hours and supports transparent, verifiable transactions in the recycled plastics market. PuriChecker received a CES 2026 Innovation Award in the Human Security for All category.